OSHA noise exposure standards are frequently exceeded due to compressed air blowing. The problem is that conventional air cannons produce a lot of turbulence, which results in loud and unsafe noise levels.

It is feasible to lower the noise level and reduce turbulence by using reliable safety air blow guns. When an employee's noise exposure equals or exceeds an 8-hour time-weighted average sound level of 85 dB, OSHA's Hearing Conservation Program will be initiated (A).

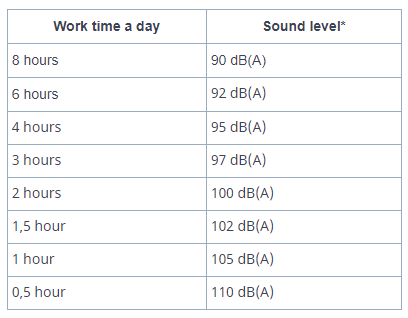

Depending on the volume of the sound, you are only allowed to work for the following amount of time each day, under OSHA 1910.95:

* The sound pressure level shown in the table is the A-weighted equivalent sound pressure level (dB(A)), calculated over a certain time interval.

It is feasible to maintain the sound level at a legal level and avoid OSHA's Hearing Conservation Program by swapping out conventional air guns, which frequently exceed these limitations, with OSHA-compliant air blow guns from Silvent. For use in the manufacturing sector, Silvent air blow guns are created with safe, quiet, and effective blowing in mind.

Act to reduce the volume to a reasonable level

The impacted employer must take steps to reduce the 8-hour time-weighted average sound level below 85 dB in order to leave the OSHA Hearing Conservation Program (A). There are several options for how to approach this. Administrative or engineering controls are used in step one, and all impacted personnel should be given personal protective equipment (PPE), which the employer must make sure is worn, in step two. The firm will be required to pay a fine if the noise level is not reduced to an appropriate level or if the PPE is not worn properly.

The provision of solutions that produce less noise is the first step in avoiding restricting the amount of time that workers may work. Changing associated equipment is the most effective way to reduce noise because compressed air blowing is one of the major sources.

The air blow guns made by Silvent that comply with OSHA feature unique technology that can lower noise levels by as much as 50%. While doing so, operators have access to strong blowing forces. The silent air blow guns allow for extended work periods without exceeding the allowed noise exposure levels.

The air blow guns made by Silvent that comply with OSHA feature unique technology that can lower noise levels by as much as 50%. While doing so, operators have access to strong blowing forces. The silent air blow guns allow for extended work periods without exceeding the allowed noise exposure levels.

Additionally, the nozzle is made to eliminate the possibility of a complete blockage, allowing the air blow guns to operate well without reducing the pressure. Learn more about how Silvent's air blowguns avoid a breach of OSHA 1910.242 compliance (b).

Our Spray Nozzle Engineering professional team can assist you in locating a secure, silent, effective, and efficient compressed air-blowing application.