Getting rid of the gummy flavouring buildup in tanks

All tank sizes that have particularly sticky residues benefit from powerful jet-cleaning devices.

Smaller containers, however, frequently cannot employ traditional jet cleaning systems due to cycle duration and water consumption. These containers will either overfill with the cleaning agent or consume too much water in general as a result of the prolonged cycle periods.

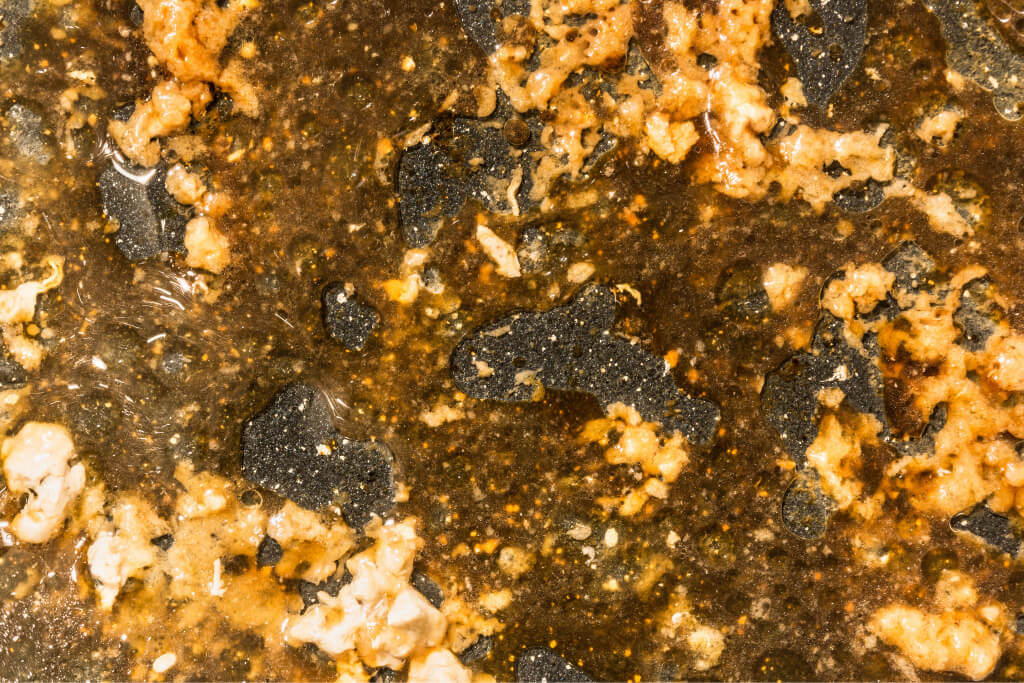

Sticky stains in small tanks

There were issues with cleaning the barrels of flavour concentrate utilised on the production line of a well-known potato chip maker.

The barrels had a diameter of only 24 inches, but the residue they contained was sticky and difficult to remove. Additional hand cleaning was necessary since the spinning spray balls that were supposed to do the job weren't sufficient.

The spinners, which are typically used in tiny tanks, were not adequate for the task because of the viscous, sticky residue. This is despite the fact that the barrels are relatively small containers. Another problem was that the majority of rotary jet cleaners were too bulky and had too much flow to be useful. Most rotary jet cleaners need a predetermined cycle period of 10 minutes or longer to make sure the jets hit every area of the tank. This cycle is unsuitable for the manufacturer.

The BETE HydroWhirl® Orbitor 100 serves as a fix.

A quick-cycle compact rotary jet cleaner called the HydroWhirl Orbitor 100 tank cleaning machine was supplied by BETE. Fast rotation of the Orbitor 100's cleaning cycle allows for two-minute complete cleans. Additionally, it operates at a lower flow rate, similar to that of a spinning spray ball, allowing for effective delivery of forceful impact cleaning while using less water overall.

The result?

Following testing against a number of rival machines, the HydroWhirl Orbitor 100 was chosen. It was thought to be a more durable machine that would last longer and need less maintenance since it provided a better overall clean.

Saving time and money, the Orbitor 100's impact cleaning guarantees that the barrels are washed without the need for a second manual clean. The Orbitors sturdy and beautiful design also ensures that maintenance problems are less common than with other competing products, resulting in less downtime.